Glass is an important component in daily industrial production. Various types of industrial substrates, display panels, civil glass, and display cover plates in the electronics industry need to use glass drilling technology. The traditional glass drilling process often has difficulties such as high brittleness, high hardness, poor heat dissipation, large thermal expansion coefficient, and difficult clamping and positioning, and the processing is greatly limited.

In order to solve many problems in the traditional glass drilling process, a nanosecond green laser was born recently. It is understood that this laser adopts the processing method of galvanometer drilling, and uses the point-by-point action of a single pulse on the base material, and the laser focus moves quickly on the glass according to the predetermined design path to realize the removal of the glass material. Based on this technology, bottom-to-top processing, the laser passes through the material and focuses on the lower surface of the material, starting from the bottom to remove the material layer by layer. In the process of processing, the material will not appear taper, and the upper and lower apertures will be the same, enabling high-precision and efficient "digital" glass drilling. The characteristics of this nanosecond green laser are summarized as follows: fast speed, high precision, good stability, non-contact processing, and high yield. The minimum diameter of its processing aperture is 0.1mm, and it can process arbitrary shapes such as square holes, round holes, and stepped holes.

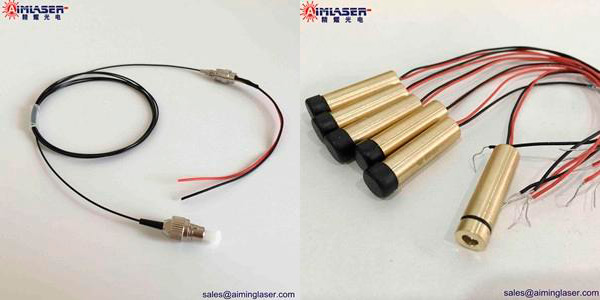

Regarding the two technical routes of optical fiber and solid state, there is actually no difference between the two, but each has its own characteristics. The solid-state laser has high peak power and high single-pulse energy, and belongs to the sprinter with strong explosive power, while the fiber laser has high average power, high repetition frequency, and good long-term stability, which belongs to the long-distance runner. For example, in terms of cutting brittle materials, solid-state lasers have high single-pulse energy, can cut thick glass, and have better end face effects. Fiber lasers, on the other hand, cannot process thicker materials quickly because they cannot withstand high single-pulse energies. However, in the processing of thin materials, fiber lasers are gradually accepted by the market due to their advantages in efficiency, price and stability.

As we all know, it is difficult to increase the power of solid-state lasers, but it is relatively simple to increase the power of fiber lasers. When industrial processing needs to be accelerated, fiber lasers can quickly meet customer needs through an increase in average power, but solid-state lasers often require longer R&D cycles and higher R&D costs. In the long run, the optical fiber technology route will definitely become the mainstream choice in the high-power short-wavelength laser market, and one of the core factors is price.