There are various traditional industrial cleaning methods, but most of them use chemical agents and mechanical methods for cleaning. As China's environmental protection laws and regulations are more and more strict, people's awareness of environmental protection and safety is increasingly enhanced, how to find a cleaner, and non-damaging cleaning way has become a problem we have to consider. Laser cleaning has no grinding, no contact, no thermal effect and suitable for all kinds of material objects cleaning characteristics, is considered to be the most reliable, the most effective solution. At the same time, laser cleaning can solve the problems that cannot be solved by traditional cleaning methods.

From the nature of the laser, laser and the light around us together (visible light and invisible light) is no different, but the laser is to use the optical resonator gathered together in the same direction, and has a simple wavelength, coordination performance is better, so in theory all wavelengths of light can be used to form the laser, But in fact, limited by the limited excited medium, can produce a stable and suitable for industrial production of laser light source is quite limited. Nd: YAG laser, carbon dioxide laser and excimer laser are widely used.Nd: YAG laser can be transmitted through optical fiber, which is more suitable for industrial applications, so it is also used in laser cleaning.

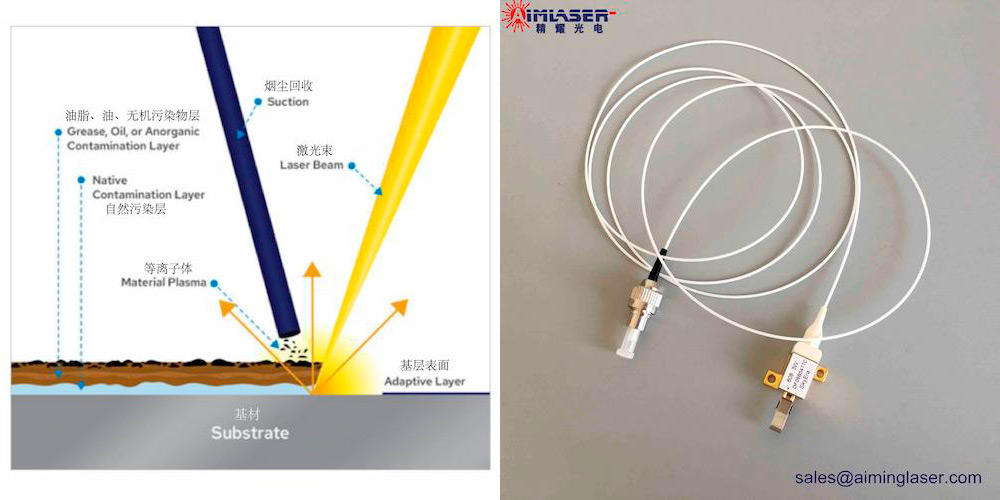

Laser cleaning is based on the optical physical reaction caused by the interaction between the high intensity beam, the short pulse laser and the polluted layer. Its physical principles are summarized as follows:

1. The beam emitted by the laser is absorbed by the surface pollution layer that needs to be processed.

2. the absorption of large energy to form a rapidly expanding plasma (highly ionized unstable gas), producing shock waves.

3. the shock wave causes the pollutants to be broken into pieces and removed.

Compared with traditional cleaning methods such as chemical corrosion cleaning, liquid-solid strong impact cleaning and high-frequency ultrasonic cleaning, laser cleaning has obvious advantages.

1. No need for any chemical cleaning liquid, safe and environmental protection.

2. Non-contact cleaning, do not damage parts matrix.

3. Simple operation, hand-held or with manipulator to achieve automatic cleaning, to achieve remote operation.

4. Precise cleaning, can realize the precise position, precise size selective cleaning.

5. High cleaning efficiency, save time.

6. The laser cleaning system is stable and can work for a long time.

Laser cleaning can not only be used to clean organic pollutants, but also can be used to clean inorganic materials, including metal corrosion, metal particles, dust and so on. The main applications are as follows:

1. Remove rust from the metal surface.

2. Surface oil, dirt, dirt cleaning.

3. Surface coating and coating removal.

4. Pretreatment and post-treatment of welded/sprayed surface.

5. Dust and fixtures shall be removed from the surface of stone carvings and statues.

6. Cleaning the residue of rubber mold.