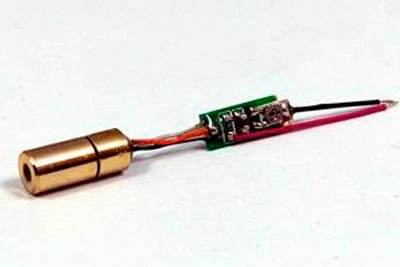

Semiconductor laser, commonly known as a laser diode, is composed of fiber coupling semiconductor laser module, beam combination device, laser energy transmission cable, power system, control system, and mechanical structure, in the power system and control system drive and monitoring to achieve laser output. The commonly used working substances of semiconductor lasers are GaAs, CdS, InP, ZnS, and so on. There are three main excitation modes according to different working substances: electric injection, pump type, and high energy electron beam excitation.

incentives | working principle |

Electrically injected semiconductor laser | GaAS, CdS, InP and ZnS are used as working materials to make semiconductor diodes. When electrically injected, the working materials are excited by the current injected along the forward bias, so as to generate stimulated emission in the nodal plane region. |

Punp laser | The population inversion can be realized by using p-type or N-type semiconductor single crystal as the working material and by pump excitation from other lasers. |

High energy electron beam excited laser | P-type semiconductor single crystals (PbS, CbS and ZnO) or N-type semiconductor single crystals were used as working materials and excited by lasers from other lasers. |

![]()

Because of the development characteristics of high integration, high speed, and tunability, in recent years, the development of low-power semiconductor lasers used in the field of information technology is extremely fast, which makes the laser diode have great innovation and progress. At present, with the support of research projects in various countries, semiconductor laser chip structure, epitaxial growth, and device packaging, and other laser technologies have made great progress, the performance of unit devices has also achieved a breakthrough: The electro-optic conversion efficiency is more than 70%, and the beam divergence Angle is lower and lower. The cooling efficiency of the laser is increased by 30% by using a carbon nano (CN) heat sink, and the continuous working life of the laser is tens of thousands of hours.

Semiconductor laser has small volume, lightweight, long service life, high reliability, low energy consumption operation, the electro-optic conversion efficiency is high, the advantages of easy to mass production and the price is cheap, in a disc, or CD machine, optical fiber communication, optical storage, laser printers, and other wide applications, covering the entire field of optoelectronics.

With the continuous development and breakthrough of technology, the semiconductor laser is developing in the direction of shorter emission wavelength, larger emission power, ultra-small, and long life, to meet the needs of various applications, the product category is increasingly rich. It has also been widely used in laser processing, 3D printing, lidar, laser ranging, military, medical and life sciences. In addition, high-power direct semiconductor lasers are widely used in cutting and welding fields by coupling into optical fibers for transmission.