In recent years, laser technology has been developed rapidly and is familiar to people. Its application fields mainly include industrial manufacturing, national defense, communications, medical beauty, consumer entertainment, etc. For different fields, scenes, laser wavelength, power, beam, intensity, pulse width and other properties are not the same, in reality, few people will understand the performance parameters of the laser. At present, the laser can be divided into crystal luminescent solid state laser, gas laser, fiber laser, semiconductor laser, chemical liquid laser and so on.

In the past 10 years, fiber laser is undoubtedly the star of the industrial laser. The development and progress of fiber laser, to a certain extent, is due to the development of semiconductor laser, especially the localization, laser chip and pump source and other core devices are actually semiconductor laser.

![]()

Before this, many people are optimistic about the market potential of industrial semiconductor lasers, because in terms of electro-optical conversion efficiency, solid YAG lasers and CO2 lasers are about 15%, fiber lasers can reach 30%, and semiconductor lasers can be done with 45% industry, the laboratory has done 70%. This means that the output of the same power laser beam, semiconductor laser more energy saving, energy saving is money, for users to save money on equipment products will certainly be popular. Therefore, many experts believe that semiconductor lasers will become the most promising lasers.

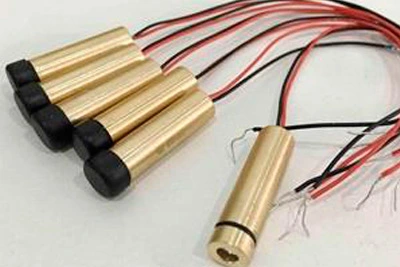

Semiconductor lasers used in industrial processing are generally divided into two modes: direct output and fiber coupling output. The beam of direct output semiconductor laser is rectangular, easy to be affected by back reflection, dust and other factors, the price is slightly cheaper; The optical fiber coupled semiconductor laser beam is round, can avoid the interference of back reflection and dust, and can integrate the robot to achieve flexible processing, but the price is expensive. Compared to the fiber coupled laser diode, the beam quality of the semiconductor laser is almost, so it is rarely used for cutting, the most widely used semiconductor laser is marking, metal welding, cladding, hardening, and plastic welding applications.

Semiconductor lasers are of great use in welding and cladding. Semiconductor laser has been very mature in the brazing of automobile body, and has been assembled in the production line of some models such as Volkswagen and Audi. General steel welding is also an important application of semiconductor laser, in addition to hardware processing, ships, rail transit and other important application fields. In recent two years, the new blue light semiconductor laser has excellent application potential in copper materials, motors, cells and other products. In addition, laser cladding has an important role and value in the repair and renovation of core metal parts in heavy industry and construction machinery industry. Semiconductor laser is the most popular laser for laser cladding. With the country to further promote the "new infrastructure" development strategy, will also drive the application of laser cladding, semiconductor laser is a great benefit.